As Bentley Mulliner’s Speed Six Continuation series enters the production stage, we speak to the division’s special projects leader Ben Linde about the programme – and what the future holds.

“I think it was for us to prove the naysayers wrong, and we have done that,” he says. “They said we were not going to produce true Continuation cars, and we have.”

He is in a positive mood: the 12 Bentley Blowers have already been delivered, and Mulliner is halfway through the Speed Six project, which recreates the models raced at the Le Mans 24 Hours in 1930. “We’ve just delivered the first car, and we’ve got another five in production at different stages; we hope to have them all finished by the end of 2025.”

The 12 Bentley Blowers have already been delivered, and Mulliner is halfway through the Speed Six project

The process has been exhaustive. While the company’s own Speed Six, GU 409, was used as a reference, the project also benefitted from having Old Number 3 loaned to Mulliner. That car was driven in 1930’s Le Mans race by Sammy Davis and Clive Dunfee – however, the research went much further than that.

“I describe it as being a bit like the Jurassic Park DNA – you’re getting pieces from all over, and then we as engineers have to act as detectives to ensure we are creating authenticity,” Ben says. “We’ve got huge amounts of data in the WO Bentley Memorial Foundation, in terms of drawings as well as physical assets. We recognise that there’s been plenty of change over 90 years, and then we consult industry experts for their learnings over 50-plus years restoring these cars. It’s all about piecing together the history.”

While the original models provided the starting point for the 3D geometry, these were overlaid with the original drawings to analyse any concerns as the car was put together. Yet even this presented some challenges. “At the time, Bentley was creating drawings with very little money, and some were done in France because the labour was cheaper at the time, so we’ve had to become fluent in French,” Ben smiles – although that was only one of the early challenges. “We’ve got a lot of examples of where parts don’t fit together. They’ll have modified them at the time and not updated the drawing.”

Where there have been changes to the original cars, it’s been down to usability: “Looking at the pedal-shaft assembly, if we took that from the original 1929 drawing, it’d be difficult for a modern customer to get their feet on the pedals – so we’ve had to make subtle adjustments such as that.”

Thoughts are now turning to what’s coming next. “We don’t want to stop the development of coachbuilding skills we’ve had over the past four or five years – but we want to make sure the next step is the right one,” Ben explains. “We don’t want to do a programme just for the sake of it.”

Could the next project be something post-war? “We wanted to celebrate our history around Le Mans, and we have done that successfully – but I don’t want to restrict ourselves to pre- war. The skills we’ve developed could apply to classics in general,” he says.

These talents could see Mulliner refitting and retrimming more recent Bentleys, even up to 1990s Continentals and beyond: “I’d relish the chance to access that kind of car; there are a lot of things we could do to reimagine those models sympathetically.”

Ben believes the programme has had a far-reaching impact beyond the cars – and Bentley itself. “There’s a lot of stuff where I think assumptions were made over the decades, with different tech and mechanisms,” he says. “The research and validation we’ve been able to do as part of these programmes are something we’re able to offer back into the industry.”

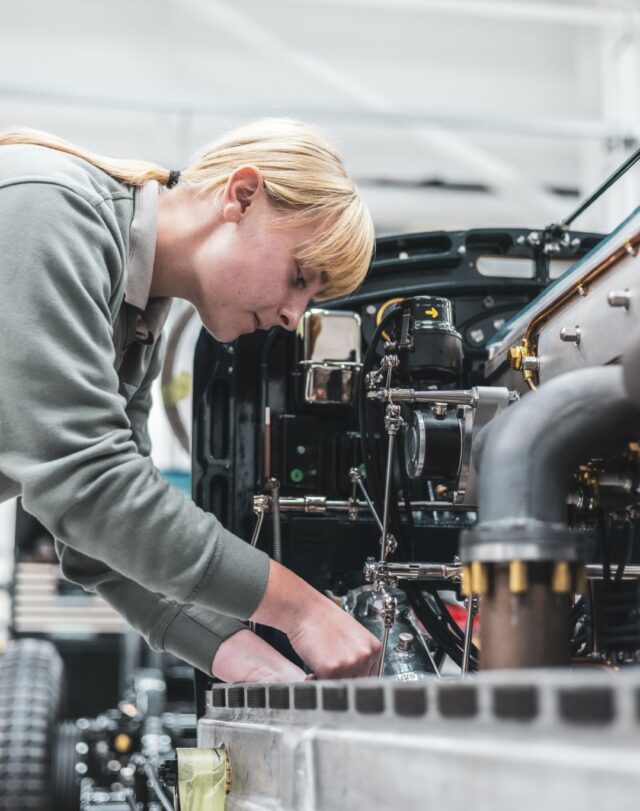

He also sees the investment in the next generation of coachbuilding craft as a great legacy. Many of those involved in the Continuation projects are apprentices, learning coachbuilding skills from long-term experts dating back to the Rolls-Royce/Bentley days.

“Looking through books, drawings and physical parts, as well as learning new ‘old’ skills, is something the apprentices have really enjoyed,” Ben says. “They’re getting their hands dirty, becoming fully involved with a car, rather than ‘just bolt this here please’ – this is what makes Mulliner unique.”

More details here.