WORDS: NATHAN CHADWICK | PHOTOS: AMY SHORE

Allesley, near Coventry, might not spring to mind when it comes to being the cutting edge of automotive design and engineering. Yet think of any high-end, low-volume luxury or performance car from a UK manufacturer, and it is likely the route from prototype to production began behind the doors of the beautiful Art Deco HQ of HPL Prototypes. Now, the village’s name is being loaned to a new offshoot from the main company, catering to the needs of individual private clients for bespoke creations.

I think the move to electric cars means more people will want to have their own signature on their car

“There’s currently no independent coachbuilding in the UK,” says Allesley CEO Paul Abercrombie. “Obviously Rolls-Royce has its coachbuilt programme for individuals, but it’s not independent for private clients across different brands. We are not manufacturers of bodykits, modifiers of performance cars or general mechanics, and we never will be. We are special luxury coachbuilders creating unique bespoke motor cars for bespoke clients and OEMs, working with luxury brands and the world’s finest vehicles.”

HPL Prototypes’ building and the associated workshops have engineering heritage dating back to the 1930s, starting with aeronautics – including building parts for the Supermarine Spitfire engine. In the 1950s the building played host to the Rover and Triumph racing development team, before becoming the assembly and service department in the 1960s, which included work on the Rover SD1. In the 1980s the site was taken over by MGA Developments, with such concept work as the Bentley Java, Ford Escort RS Cosworth and McLaren F1. In the 1990s, the space was used by Lotus to deliver such prototypes as the Elise and Opel Speedster.

For the past 25 years HPL Prototypes has been providing concept services to OEMs – so what’s behind the move to opening a private coachbuilding company? “We’ve done two projects for an individual, but that was as HPL Prototypes; that was just two vehicles we wanted to do, and we hadn’t actively looked for that sort of work before. We decided, as it’s the 25-year anniversary of HPL, that we’d set this business up and start actively addressing that side of the market,” says Chris Devane, Allesley chairman and HPL Prototypes CEO.

“We’re learning a different language, because we’re used to dealing with industry professionals – whereas [they] might talk about H-points, rollover protection and torsional stiffness, some [individual] customers may speak a different language. That’s why we needed a dedicated, separate business – we need to spend more time with these private clients, and Paul has experience doing that with properties and vehicles.”

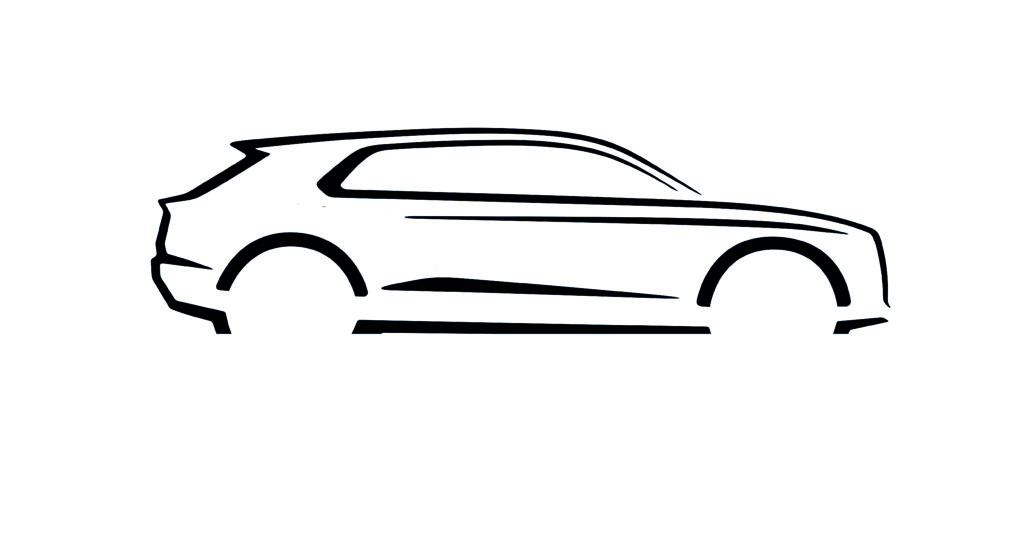

The first fruits of that labour are teased in the picture above – a high-end, ultra-luxury SUV that features a new coachbuilt body. The full reveal will be next year; however, there are several other projects under way already. Magneto took the opportunity to look behind the scenes at just what a modern British take on coachbuilding means.

While HPL Prototypes, and thus Allesley, still work with clay, at both the main HQ and a satellite location in Crewe, the design stage is usually a mixture of digital and physical realisation, although this depends on the client.”We have one client who just wants hand-drawn sketches and watercolours, because he wants to display them as artwork – he’s just not interested in a render. That’s the language he understands, as a fashion designer,” says Paul.

“However, you can do [great things] with with mixed and augmented reality, with pedals and a steering column. It all depends on the client and how much they are willing to invest. It also depends on the level of changes; if you’re not changing ‘that’ part of the car, it doesn’t make much sense to do that sort of simulation. However, if you’re changing fundamentals such as the ergonomics, then it probably is worth doing.”

Yet VR is certainly a worthwhile marketing tool, Paul believes: “If you come to see us in 12 months’ time at a show, you may see a combination of a full-scale model with a seat you can sit in with a headset on, to make you feel like you’re inside the interior of the car,” he says. “That’s how we can configure all the different colours; that’s an entry point for a client to understand the possibilities of coachbuilding.”

Allesley is setting up a dedicated space for VR activities at its HQ. “We’ve worked on projects where we’ve used CMF or colour material finishes; we’ve researched the online presence of the client, looked at their favourite colours, and the jewellery and watches the person may like, and then tailor the car before they arrive based on their preferences, their colour preferences,” says Chris. “Then they can put the headsets on and walk around the car.”

However, not everyone likes the VR experience; some prefer something they feel and touch. “We can do full-size foam models; we’ve had clients who said, you’re looking at 0.5mm zoomed in massively – we need to look at it in scale, which is one to one,” explains Chris. “So we’ve done either quarter- or full-scale models. We did a quarter-scale model in clay for one client, and he took it away with him. He showed all his friends, and they added clay onto it and then brought it back. We got the feeling of what he wanted to do, and that was part of the experience for him.”

While VR has its benefits, it also has its drawbacks, says Chris: “Sometimes you can zoom into really fine detail in VR and you’re chasing perfection, and when you see it in real life, you can’t really see it at all because it’s such a tiny detail.

“Quite often people ask why we are making physical things, why don’t we just go from digital straight into the real car? My argument is, why have you got travel insurance? You never use it, why don’t you just fly without it? Because if you go from the digital straight to the real car, you are taking a chance that it’s too late. By the time you get the car, if you don’t like it, it’s too late. It’s better to make something in between to mature the quality.”

The possibilities of coachbuilding are almost endless, given enough time and money, but the thorny issues of intellectual property rights and brand perception are considerations that have to be gently explained to the clients. “The iconography of a brand of an OEM is very important,” says Paul. “If the client wants to stray from that, and be so radical in their design that they come away from the iconography of the car, then there becomes a point where that’s a step too far.

“[We would] have to inform the client that the car can no longer be branded as, say, a Bentley or an Aston Martin. It would have to then be the client’s own vehicle under his or her own banner, family crest or badge. It’s a fine line – and that’s where HPL’s relationships with OEMs come in. We can sit down and discuss any issues with OEMs, and come up with clear working relationships and a path moving forward.”

Considering that OEM partners such as Bentley, McLaren, Aston Martin and Rolls-Royce have their own bespoke departments – Mulliner, MSO, Q and Bespoke respectively – you might think there’d be some alarm at Allesley’s formation. Not so, says Paul. “Everybody we’ve spoken to has acknowledged the need for a UK-based coachbuilder,” he says, pointing to the difficulty for true one-off or even limited-run cars to be adapted into modern production lines. “We can service some of the OEM work in future, because there’s an increased need for OEMs to have one-off cars or one-of-ten collections. Looking at it from that context, OEMs are very much supportive.”

“They’re all very positive,” Chris adds. “They see the need, and they’re wishing us every success and want to work with us going forward.

Such close co-operation with OEMs means Allesley, through HPL, understands how complex modern electrical systems are – and it’s not something that Allesley would change directly; any alterations would work in tandem with those systems. Powertrain changes would also need to be thoroughly tested, Chris says: “If someone wants to put a much more powerful engine in a car, the challenge for us would be to ascertain whether it is useable power – is the chassis up to it?

“We’d recommend a development programme with our partners MIRA and Millbrook [UK testing facilities], and have a shortened development period with a mule, doing high-speed and stability assessments. We’d have to be careful about cooling, fuelling and all sorts of things that adds lots more complexity into the project. If a client is adamant that’s what they want to do, we would do it in a way that has quality built in, safely.”

While the first few projects are based on internal-combustion engines, Allesley is already looking to the future. Chris believes EV architecture opens up more possibilities for coachbuilding. “If you’ve essentially got a skateboard chassis, it has to be strong because of the batteries,” he muses. “That means the cabin or the body structure provide more freedom – you have the ability to use composite panels, or aluminium or steel. However, composites are lighter and you can do more radical things with shapes – we have our own composites centre here, so we can do carbon.”

The choice of material would depend on the project, though, according to Chris. “If it was an historic car, a restomod historic car, and composites were not an option, then we could look at hammer-formed or wheeled-aluminium panels, or super-form panels, if that’s what they want.”

While traditional restorations are not the main focus, a restomod concept isn’t outside the realms of possibility. “A bespoke-built E-type, for example, with a bespoke interior and a heavily modified body to the likes and taste of the client – we would definitely engage with that for a client as a one-off project,” Paul says. “However, for our one-to-one private-commission service, we very much want to focus on contemporary coachbuilding on modern cars that are being released now, and tailoring them to the client’s wants and desires.”

For Allesley projects, the clients would purchase donor cars from their local dealers, largely because unloading a semi-completed car from a production line just isn’t possible in today’s just-in-time manufacturing process. “We feel it’s best that the client purchases the car in their environment or marketplace, so it will be homologated for that region, rather than buying a car in the UK and then trying to convert it, or buying a left-hand-drive car in France and then selling it somewhere else,” Chris says. “It’s also good that the dealer knows that car, because if there are any issues with it from a servicing point of view, the dealer knows the car. We will look after all the bespoke parts.”

Allesley has allocated five build areas in a dedicated facility next to the HPL Prototypes buildings for the project, which will also leverage HPL’s various other workshops. The plan is to deliver 30 Allesley vehicles in first five years, with three cars currently in build.

That may seem ambitious, but the Allesley team references a recent McKinsey study that has pointed to the luxury automotive sector as being a hugely growing market, driven by the Middle East and China. “The last financial year saw a record number of £2m-plus cars sold globally around the world, and every OEM is projecting that it’s going to grow year on year between now and 2035,” says Paul. “I think the move to electric cars means more people will want to have their own signature on their car.

“There currently isn’t the noise characteristic on electric cars, so I think that people will want to differentiate more with the shape of the car as a whole, and the interiors. There’s a potentially big market globally, but we’re keen to be based in the UK – the technical competency is here [and] it’s the home of coachbuilding.”

Find out more about Allesley here.